There are a lot of tests that can be performed to confirm a particular material in a chandelier without necessarily damaging it. Here tests for confirming most commonly used metals in lighting fixtures like brass, chrome, nickel, aluminium are explained. These metals can easily be confused with certain metals that are identical to them.

Hence, knowing these tests can help to distinguish between fake and real chandeliers.

Identify metals without damaging the metal of light fixture

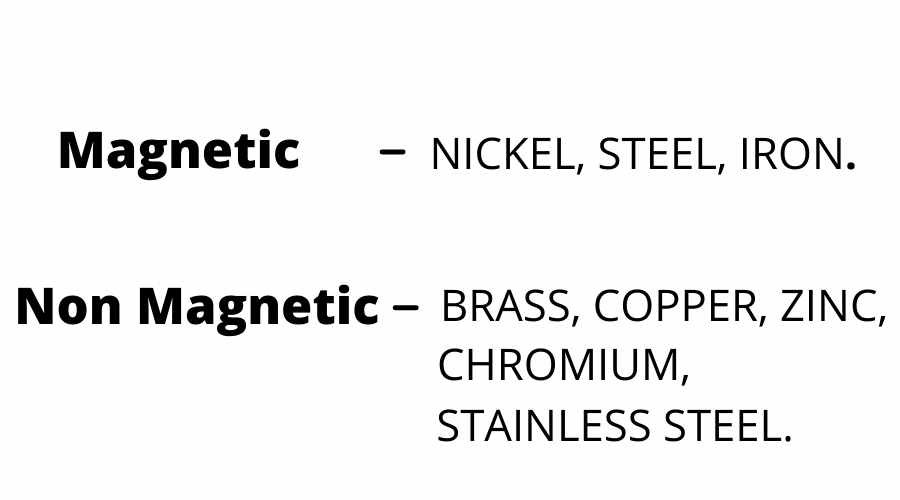

To instantly identify a particular metal knowing its magnetic properties helps a lot. The image below shows all the metals that are commonly used in lighting fixtures and which of them are magnetic as well as non-magnetic.

Lets see each metal one by one and how to spot that metal without damaging the metal.

Brass

Brass is generally plated on iron, steel, nickel, aluminum, zinc. To distinguish whether the light fixture is made up of solid brass or have some other metal with a thin layer of brass plate on it, following tests can be performed.

Magnet test

Brass is not attracted to magnets whereas if iron or steel are electroplated with brass, they will attract magnets.

Same is for nickel coated with brass. Solid brass will not be attracted to magnet whereas Nickel shows high affinity towards magnets.

Aluminium and zinc are not attracted with magnets therefore a different property of metals is used i.e Malleability (ability to be deformed into a different shape upon pressure)

Aluminium is a highly malleable metal so if it is brass plated, it will easily bend and can be restored to previous shape without getting damaged.

Sound test

To distinguish between brass and brass plated zinc, the sound each metal produces upon hitting can be observed. Since brass is an alloy of zinc and copper and hence is much heavier than solid zinc. Upon hitting with a spoon or coin, the brass will produce a sound of heavy tone compared to brass-plated zinc which is easily distinguishable.with a tone of slightly higher pitch.

NICKEL

Nickel is a silvery white metal. When polished, it almost looks like chromium while brushed nickel have a slightly brownish shade to it. In light fixtures both brushed as well as polished nickel is used.

However, Nickel can also be plated on metals like aluminium, brass, stainless steel, copper, zinc. To check, whether the metal is pure nickel or some other metal that have a thin layer of nickel-plated on it perform the magnet test.

Nickel is attracted to magnets while brass, zinc, copper, stainless steel are not attracted to magnets. If the magnet sticks, the metal is either nickel or nickel-plated steel. Again to further confirm solid nickel, malleability test can be performed.

Since steel is less malleable compared to nickel. If the metal bends upon allying force, it is confirmed that the metal is nickel.

CHROMIUM

Chrome is electroplated plated on metals like iron,steel,nickel,aluminium,zinc. To distinguish whether the light fixture is made up of solid chrome or have some other metal with a thin layer of chrome on it following tests can be performed.

Sound test

Chromium is a very light metal upon hitting with a coin it produces a sound of high pitch whereas stainless steel with chrome plated on it will produce a sound that have a relatively low pitch.

Magnet test

Chrome is not attracted to magnets therefore, if magnet sticks with the metal of light fixture it can either have iron, nickel or steel with a thin layer of chrome on top.

If the magnet does not sticks then still, the metal can be either solid chrome or stainless steel. Stainless steel is much hard and stronger compared to chrome Trying applying some force on thin parts of light fixture to see if the metal bends or not can help identify the particular metal.

If metal bends, it is either chrome or chrome plated aluminium and if it does not the metal is stainless steel.

To get more accurate confirmation tests involving chemicals are required.

More intensive tests to precisely confirm a particular metal in chandelier?

Chandeliers come in various metals like brass, nickel, iron, stainless steel, chrome etc. Below are useful tests for identifying each metal.

Brass

Brass resembles to gold in appearance as it have yellow luster.Brass is an alloy of zinc and copper.The property of brass directly depends upon the amount of zinc and copper added. For example, if brass have high copper content (>35%), the brass will have higher strength but have lower malleability. Malleability means the ability to get deformed upon pressure without breaking.

Scratching the metal

This test is based on the fact that the plated brass in a very thin layer of brass. If the metal is scratched and it yellow shiny scratches are observed within, the metal is surely brass and if instead of yellow scratches, white scratches are observes, then the metal is zinc electroplated on brass.

Nickel

Nickel is the most easy metal to identify. Nickel is a highty attracted to magnets These are the tests which can be performed to identify nickel.

Spot test

A solution for testing nickel can be found online. Simply a cotton ball is dipped in the solution then is rubbed on the metal surface.

If the cotton turns pink the metal is confirmed to be nickel.

Nickel also is plated on steel. Just by looking at steel plated nickel and solid nickel it is hard to tell which is solid and which one is plated. Also both of them have almost similar weight. So to be confirmed about the solid nickel perform the next test

Corrosion test

This test is based on the fact that solid nickel does not develop rust if exposed to salt solution.

Scratch the metal surface to expose the steel if any and then immerse that part in salt and vinegar solution for a few days and observe if any rust is developed on it. If rust develops then the metal is clearly steel plated with nickel. As solid nickel is rust-resistant

How to identify Aluminium in chandelier

To most common metal used instead of aluminium in light fixtures is tin. As they can be mistaken for one another.

Both aluminium and tin are malleable and have almost similar appearance. But just with the help of a magnet, aluminium can be distinguished from tin.

Aluminium is not attracted to magnet whereas tin is attracted to magnet.

Now magnet test eliminated tin. Now there are many other metals that are attracted to magnets like steel, iron. So to confirm, that the metal is aluminum, try bending or applying pressure on the metal, if the metal deforms, surely it is aluminium as steel and iron does not deform easily.

Also by the weight of metal one can tell whether its aluminium or not as aluminium is light weight compared to iron, steel

How to identify chromium in chandeliers

Chromium used in lighting is a very shiny metal. Stainless steel also provides identical shining as chromium.

Chrome plating is performed on metals like steel, aluminium, plastics, copper alloys, zinc alloys etc.

To differentiate solid chrome from chrome-plated steel, one can perform the corrosion test (putting the metal in a solution of vinegar and salt). Chromium is highly resistant to corrosion while steel will corrode.

To differentiate solid chrome from pated “stainless steel”, special chemicals like (chrome stripping solutions) are required since both chrome and stainless steel are highly resistant to corrosion as well as both are not attracted to magnets.

The solution when rubbed over chrome metal with a cotton ball, the solution will turn yellow watch the video below from (1:28 – 3:03)

Whereas if the solution is rubbed over chrome-plated stainless then the solution will turn yellow and will expose a brownish color material underneath the chrome plating i.e Nickel which is added over stainless steel before electroplating it with chrome.

To distinguish between solid chrome from chrome-plated copper, simply scratch the surface such that the thin layer of chrome is removed and copper gets exposed. Soon a brownish colored metal copper can be seen.

To further confirm that it is copper put some vinegar on a paper towel and put that paper on the scratched metal surface. On chrome plated copper, a dark greenish coating will be formed as copper reacted with acid in the vinegar

to form copper acetate. While no reaction will happen on solid chrome.

Distinguishing between chrome and chrome plated zinc is also easy. Zinc is a very grayish color metal as heavy compared to chromium. If chrome is plated over zinc then simply scratch the metal surface just to get rid of the thin layer of chrome. If upon scratching, a grayish-colored metal is observed, then it is clearly zinc.